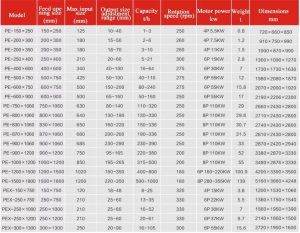

Product Application Jaw crusher is mainly used for the medium-granularity crushing of all kinds of ores and large materials in mine, metallurgy, building material, highway, railway, water conservancy and chemistry. The maximum compression strength of the materials to be crushed is 320MPa.

1. It adopts world-level manufacturing technology and high-end manufacturing materials.

2. More advanced movable jaw assembly makes it more durable. The movable jaw assembly uses high-quality steel casting and drives through two large-sized cast steel flywheels. In addition, the heavy eccentric shaft also adopts forging stock which makes JC series jaw crusher have extraordinary reliability.

3. The bearing pedestal adopts unitary cast steel structure. The unitary cast steel bearing pedestal can ensure comprehensive fitting with the crusher rack, and at the same time, greatly increase the radial strength of the bearing pedestal, whereas split type bearing pedestal does not have these advantages.

The working manner of this series crushing machine is dynamic extrusion type, and its working principle goes like this: the electro motor drives the belt and belt wheel to make the movable jaw to move up and down through the eccentric shaft, and then movable jaw goes up, the angle between the toggle pate and the movable jaw is bigger, thus pushing the movable jaw to get close to the fixed jaw, and at the same time, the materials are crushed or smashed, thus reaching the goal of crushing; when the movable jaw goes down, the angle between the toggle pate and the movable jaw is smaller, under the effect of the draw bar and the spring, the movable jaw moves always from the fixed jaw, and then the crushed materials will be discharged out from the lower mouth of the crushing chamber. With the continuous rotation of the electro motor, the movable jaw of the crusher will do periodic motion to crush and discharge the materials, thus realizing mass production.

1. The size of stone before crush , how many mm or inch ?

The working mode of this series jaw crusher is flexion and extrusion type. The motor drives the belt and pulley to move the jaw up and down through an eccentric shaft. When the jaw rises, the Angle between the elbow plate and the jaw increases, so as to push the jaw plate towards the fixed jaw plate. When the movable jaw descends, the Angle between the bracket and the movable jaw becomes smaller, and the movable jaw leaves the fixed jaw under the action of pull rod and spring. At this time, the broken material is discharged from the lower mouth of the crushing chamber. With the continuous rotation of the motor, the mechanical jaw is broken for periodic movement to crush and discharge materials, so as to achieve mass production.